Despite the many advantages of laser ablation, typical PLD suffers from ejection of micro scale particulates (or droplets) during the target ablation process. The deposition of such particulates is usually undesired in many applications as they can deteriorate the electrical, chemical, optical, and mechanical properties of the film. It is possible to reduce the density of the particulates with appropriate laser wavelength, laser intensity, uniform distribution of the laser density across the target spot, and careful target preparation. Nevertheless, despite such optimizations, the film surface is usually not completely smooth and particulates would still appear on the surface. Therefore, depending on the application, additional approaches may become necessary to further reduce the density and size of the particulates.

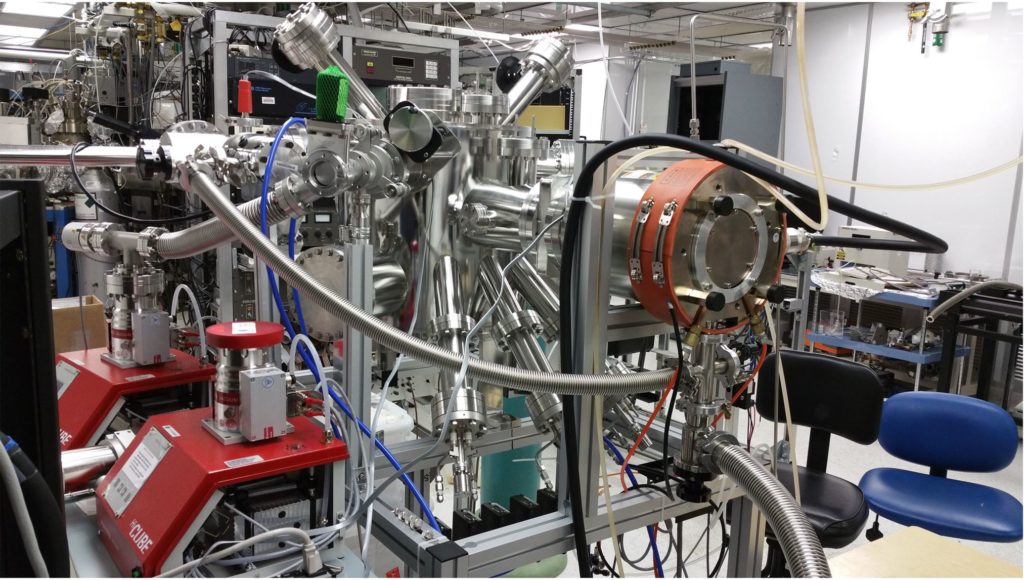

We have designed and built a customized PLD system with crossed laser beam configuration in order to efficiently eliminate the particulates. This technique was first realized by Gaponov and co-workers in 1981.[i] In our system, the laser beam is equally divided into two beams using a 50-50 beam splitter. The laser beams ablate two targets simultaneously. The idea is to create a high pressure collisional zone by intersecting two synchronized and nearly similar laser plumes from the two targets. The targets are angled with respect to each other so that the dense plasma gas from the two plumes interact dynamically and get redirected towards the substrate. However, the slow and heavy micro-scale particles continue their original path nearly normal to the target with little perturbation. The substrate is positioned along the center line normal to the trajectory of the resulted plasma flux and an aperture is used to block the particulate path towards the substrate. In this way, we can separate the trajectory of the atomic species from the particulates and achieve a nearly droplet free film.

Ultrafast Laser Ablation

As an additional step to completely eliminate the particulates and achieve perfect film quality, we have equipped our crossed beam PLD with an ultrashort pulsed laser. To date, the PLD process is primarily based on the use of nanosecond laser pulses obtained from excimer lasers. Undesirably, the nanosecond laser heating results in a fundamental drawback of the formation of droplets from the vapor phase, which are then deposited onto the substrate. The droplet formation can be avoided by changing the mode of the laser operation to ultrashort pulses. In such a mode, similar power is delivered but in much shorter pulses (< 10 ps rather than 10 ns). The energy deposition at each pulse may be three or more orders of magnitude smaller but the repetition rate can be much higher (KHz-MHz rather than Hz). Under such ultrafast pulsed laser ablation, each low energy high intensity pulse evaporates relatively few (~1011-1012) atoms;[ii],[iii] hence, inhibiting the condensation of the droplets during the plume expansion. On the other hand, the high repetition rate would keep the high average atomic flow in the plume resulting in comparative growth rate as for the case of nanosecond ablation.

The system is further equipped with three K-cells of 1500 oC that enables MBE growth of certain material compositions (Figure 1). The research focus is thermoelectric and thermomagnetic heterostructures. In both cases, films of the orders of several 10 microns thick are desired to make efficient devices. The growth of such thick films is indeed challenging due to both the excessive growth time and formation of crack or flake off of the substrate. Such cracks or flakes usually happen in thick epitaxial MBE grown films due to the build up of the internal stress. We are interested in poly-crystalline films due their lower thermal conductivity. In poly-crystalline films (grown my PLD, sputtering, etc.), the stress is released at grain boundaries enabling deposition of solid crack free thick films. The PLD growth rate is also significantly higher than MBE, which enables growing the desired thick multilayered films.

References:

[[i]] S. V. Gaponov, A. A. Gudkov, B. M. Luskin, V. I. Luchin, and N. N. Salashchenko, Formation of semiconductor films from a laser erosion plasma scattered by a heated screen, Sov. Phys. Tech. Phys. 26, 598 (1981).

[[ii]] Rode, A. V., Luther-Davies, B., and Gamaly, E. G. (1999), Ultrafast ablation with high-pulse-rate lasers. Part II: Experiments on laser deposition of amorphous carbon films, J. Appl. Phys. 85, 4222–4230.

[[iii]] Perry,M. D., Stuart, B. C., Banks, P. S., Feit, M. D., Yanovsky, V., and Rubenchik, A. M. (1999), Ultrashort-pulse laser machining of dielectric materials, J. Appl. Phys. 85, 6803–6810.